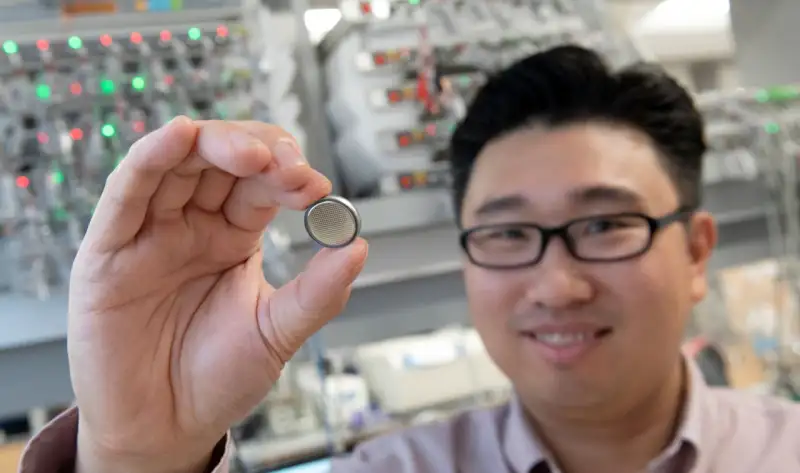

The increasing demand for lithium-ion battery-powered electric vehicles (EVs) has led to a surge in recent prices of strategic battery materials such as cobalt (Co) and nickel (Ni). While all EV makers are eager to eliminate Co usage, Ni has rapidly become another ‘pain point’ for the industry, as its price is nearing half that of Co. The sustainability issue facing both Ni and Co puts forward a grand materials challenge, that is, to reduce Ni content and eliminate Co while maintaining high specific energy and stability. In this work, a complex concentrated doping strategy is used to eliminate Co in a commercial NMC-532 cathode.

LiNi0.5Mn0.43Ti0.02Mg0.02Nb0.01Mo0.02O2 cathode shows potential cost advantage with relatively high specific energy and significantly improved overall performance (~95% capacity retained after 1,000 cycles in pouch-type cells, 2.8–4.3 V vs graphite, at 1 C, 1.5 mA cm−2). Combining X-ray techniques and electron microscopy, we uncover the origins of the superior stability.

source: nature energy